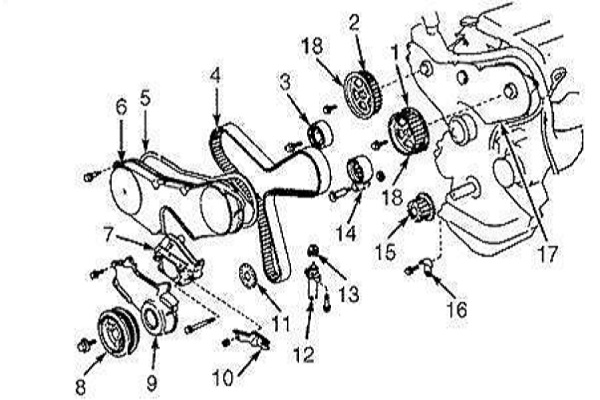

The timing belt is an important part of the engine valve distribution system. It ensures the accuracy of the intake and exhaust time by connecting with the crankshaft and matching with a certain transmission ratio. The reason for using belt instead of gear to drive is that the belt has low noise, small variation and is easy to compensate. It is obvious that the life of the belt must be shorter than that of the metal gear, so the belt should be replaced regularly.

With the continuous progress of vehicle manufacturing technology and industrial development, the timing belt of some engines has been replaced by the engine chain. Compared with the traditional belt drive, the chain drive mode has reliable transmission, good durability and can also save space. The whole system is composed of gear, chain strip, tensioning device and other components. The hydraulic tensioner can automatically adjust the tension, so that the chain tension is consistent, and free of maintenance for life. This makes it have the same life as the engine, which not only improves the safety and reliability, but also reduces the use and maintenance costs of the engine, which can be said to kill two birds with one stone.

For all engines, the timing belt must not jump or break. If the jump occurs, the engine will not work normally, which will lead to unstable idle speed, poor acceleration or failure to start; If the timing belt breaks, the engine will shut down immediately. The multi valve engine will also cause the piston to bend the top valve, and even more seriously, the engine will be damaged.

As the engine working time increases, the rubber timing belt and other accessories, such as tensioner, tensioner and water pump, will be worn or aged. Therefore, for engines equipped with timing belts, the manufacturer will have strict requirements to replace the timing belts and accessories regularly within the specified period. The timing chain made of steel with high strength can solve this problem. As we all know, the strength of metal is far greater than that of rubber, which greatly reduces its deformation, and the probability of tooth skipping and fracture is very small.

Huzhou Sanjing Auto Parts Co., Ltd

Huzhou Sanjing Auto Parts Co., Ltd